Building the 7 series

As far as is known, the better part of the design work behind the 7-series was done at the VOX AND BURNDEPT WORKS ON WEST STREET IN ERITH (click on the link for pics in a new window). This was the prototyping stage – formulating the circuit and making the various elements operate and sound as desired. Little is known of this side of things, but it may be that an American Super Beatle amp, which Denney had seen in Sepulveda in late 1965, was looked to for some of the preamp circuitry – at least as a general inspiration.

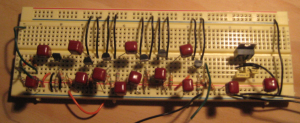

The design process is likely to have been similar to that adopted by Les Avery for slightly later lines of Vox amps. He recalls working on the “breadboards” (perforated layout boards) with Dick Denney, subbing in components by means of flying leads, and testing at each stage, until the desired effect or sound had been achieved.

Once the general design had been outlined, Triumph’s task was twofold: to set up the supply line for production (no small matter to make sure all the necessary components were delivered in sufficient quantities); then to produce the amps. It is worth saying that the resistors and capacitors etc. sourced by Triumph are distinctive (e.g. green bodied resistors, blue Philips caps): they are not found in Vox amps built in the works at Erith, ie. Burndept Electronics, a contractor, and in the Vox Factory at West Road. And these Triumph-only parts, it should be said, are also to be found in the AC50s and AC100s, as well as in the Vox PA amps, that Triumph built, but not in those built in Kent.

Basic production outline

WOODEN BOXES. Henry Glass and Co. (later constituted as “GlaRev”) made the wooden boxes, finished them – providing the tolex covering, corner protectors and vents – and sent them to Purley where they were stored (briefly) until needed. There were two basic sizes – one for the 430, 715 and 730; and another for the 460, 760, 4120 and 7120. Early boxes had removable back panels – three are known to survive – two 7120 boxes, and one 730.

CHASSIS AND PANELS. Metal was cut to order and treated by a company behind Potter’s Music Shop in Croydon. Chassis were formed up at Triumph, which had a metal press for the express purpose. When finished they were sent off to Brooklands Plating Co. in Croydon for the panels (made by Brooklands) to be fitted. Panels were attached to the chassis, and openings for potentiometers and so on drilled through both. A surviving unused panel owned by Carl Nielsen has solid metal where the holes for the front controls should be. Illustrated in J. Elyea, Vox Amplifiers, p. 461. *FOR MORE ON PANELS SEE THIS POST.

Chassis were stacked and used in no particular order, ie. an “early” one can easily occur in “late” amp. The same is true of panels. Early ones appear in amps built in late 1966.

TRANSFORMERS. Some of these seem to have been sourced from the Douglas Transformer Co., which is now in Louth, Lincolnshire – click here for its site. The transformers were evidently a particularly important “design centre”. It can hardly be an accident that 4120 and 7120-sized units (and the accompanying choke) fit on a 730 chassis – in other words in the amps that the Beatles received.

Above, top view of a 4120 chassis

ELECTRONIC ASSEMBLY. All 4-series and 7-series amps (including the ones issued to the Beatles) were assembled in the basement rooms of 118 and 122 Brighton Road described by Dave Roffey IN THIS POST. Indeed, Dave remembers working on the reverb section of the Beatles’ amps.

Doubtless some sort of basic making-up of the circuit boards – the attaching of flying leads for soldering to pots and so on – was undertaken before the final assembly of individual amps took place. One suspects that reference sheets existed at one time for this, ie. schemas of the individual boards, indicating how to wire up, what went where, what colours of wire to use. These, as time went on, probably accumulated explanatory notes.

GENERAL WORKFLOW. The various 4- and 7-series models were probably built in small batches in some sort of rotation – ie. perhaps a few 7120s, then 730s and so on. Small changes in the assembly process were introduced along the way as one might expect.

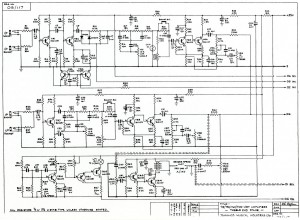

SCHEMATIC. The surviving 7-series preamp schematic is “late”, dating from after November 1966. It evidently represents a sort of tidying up (and complete sweeping away) of all that went before. Several changes of component value are noted. But it is clear from surviving amps, that a completely unrecorded value of resistor was used for a time – the reverb feedback resistor. Numerous amps have 100K. All the late schematic records is the change from 470K to 220K.

Vox-branded components – voltage selectors, for instance – presumably either came direct from the supplier or from the Burndept / Vox works at Erith.

……